In the ever-evolving world of manufacturing and packaging, efficiency, precision, and innovation drive the industry forward. A packaging production line is an essential component of modern manufacturing, ensuring the safe, hygienic, and efficient packaging of various products. From pharmaceutical packaging lines to liquid filling production lines, the integration of advanced technology is revolutionizing the sector. In this article, we explore the key aspects of a packaging production line, including types, benefits, and industry trends.

Understanding the Packaging Production Line

A packaging production line refers to a system of automated machinery designed to package products in a streamlined and efficient manner. These lines are commonly used across multiple industries, including pharmaceuticals, food and beverages, cosmetics, and chemicals. With technological advancements, modern packaging lines now feature automation, robotics, and AI-powered quality control systems.

Key Components of a Packaging Production Line

- Conveying System – Ensures the smooth movement of products through different stages of packaging.

- Filling Machines – Precisely measure and dispense liquids, powders, or granules into containers.

- Capping Machines – Securely seal bottles and containers to prevent contamination.

- Labeling Machines – Apply labels with branding, ingredient information, and barcodes.

- Quality Control Systems – Detect errors, inconsistencies, and packaging defects.

- Sealing and Wrapping Machines – Ensure products are tightly packed and protected.

Pharmaceutical Packaging Line: A Vital Industry Component

The pharmaceutical industry demands stringent packaging requirements to ensure product safety, efficacy, and compliance with global regulations. A pharmaceutical packaging line incorporates specialized equipment tailored to handle medications, vaccines, and other medical products with precision and hygiene.

Features of a Pharmaceutical Packaging Line

- Blister Packaging Machines – Ideal for tablets and capsules.

- Liquid Filling Machines – Used for syrups, injectables, and oral suspensions.

- Sterile Packaging Solutions – Ensure contamination-free pharmaceutical products.

- Tamper-Proof Sealing – Guarantees product integrity and safety.

Liquid Filling Production Line: A Crucial Manufacturing Process

A liquid filling production line is designed to efficiently package liquid-based products, such as beverages, pharmaceuticals, and personal care items. These lines come with varied automation levels, from semi-automatic to fully automatic operations.

Types of Liquid Filling Machines

- Overflow Filling Machines – Used for consistent fill levels in transparent bottles.

- Gravity Filling Machines – Ideal for thin, free-flowing liquids like juices.

- Piston Filling Machines – Suitable for thick, viscous products such as lotions and creams.

- Pump Filling Machines – Handle a variety of liquid viscosities with precision.

Liquid Oral Production Line Introduction

A liquid oral production line is specifically designed to handle oral liquid formulations, such as syrups and suspensions. These lines comply with Good Manufacturing Practices (GMP) and ensure hygienic, efficient, and contamination-free production.

Steps in a Liquid Oral Production Line

- Ingredient Mixing & Homogenization – Ensures uniform consistency.

- Sterilization & Filtration – Eliminates contaminants.

- Filling & Sealing – Precise volumetric filling and tamper-proof capping.

- Labeling & Packaging – Compliance labeling and secure packaging.

China Filling Machine Manufacturers

China filling machine manufacturers have gained global recognition for producing high-quality, cost-effective, and innovative filling machinery. These manufacturers offer a wide range of customizable solutions tailored to various industries, from pharmaceuticals to food and beverage packaging.

Why Choose China Filling Machine Manufacturers?

- Cutting-Edge Technology – Integration of AI and IoT.

- Competitive Pricing – Affordable solutions without compromising quality.

- Strict Quality Control – Adherence to international safety standards.

- Customization Options – Tailored machinery to meet specific needs.

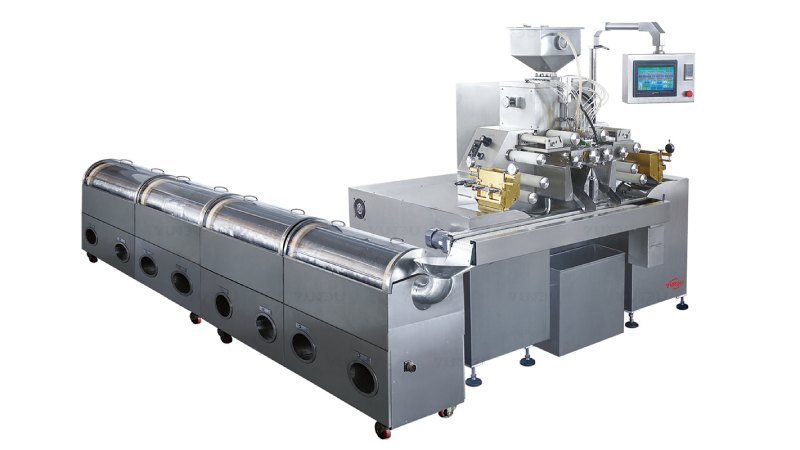

Softgel Capsule Production Line: Advanced Encapsulation Solutions

The softgel capsule production line is a specialized segment within pharmaceutical and nutraceutical manufacturing. Softgel capsules offer superior bioavailability, ease of ingestion, and enhanced stability, making them a popular choice for vitamins, dietary supplements, and pharmaceutical drugs.

Softgel Capsule Production Process

- Gelatin Preparation – Melting and mixing of gelatin-based materials.

- Encapsulation – Precise dosing of active ingredients into the softgel shell.

- Drying & Polishing – Ensuring shape retention and a professional finish.

- Inspection & Packaging – Automated quality checks and final packaging.

Final Thoughts

Packaging production lines are becoming more efficient, sustainable, and adaptable with automation, AI, and robotics shaping the future. Businesses investing in modern packaging solutions benefit from enhanced productivity, cost savings, and superior product quality.