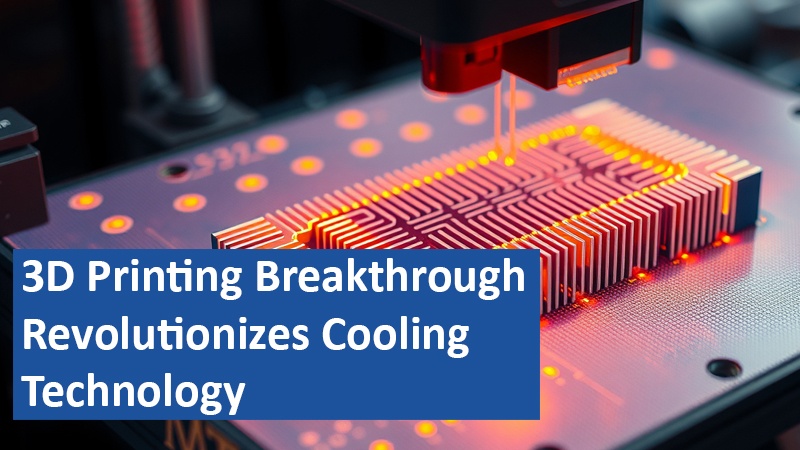

Researchers at the Institute of Science and Technology Austria (ISTA) have developed a groundbreaking method to produce thermoelectric materials using 3D printing. This innovation reduces production costs and enhances performance, opening new possibilities in cooling technology.

######################################################

Now exclusively try Amazon Prime and Prime Video free for 30 days!

##########################################################

Redefining Thermoelectric Coolers

Thermoelectric coolers, also known as solid-state refrigerators, use electric current to transfer heat from one side of the device to another. Their long lifespan, leak resistance, size adaptability, and lack of moving parts make them ideal for various cooling applications. However, traditional manufacturing methods were costly and wasteful.

Efficient 3D Printing for Cooling Materials

The team led by Maria Ibáñez at ISTA has developed a process to create high-performance thermoelectric materials using 3D printing. “Our innovative integration of 3D printing into thermoelectric cooler fabrication greatly improves manufacturing efficiency and reduces costs,” explains Shengduo Xu, the study’s lead author.

Material Savings and Enhanced Performance

The 3D printing technique allows for precise shaping of thermoelectric materials, significantly reducing material waste and energy consumption. Moreover, the printed materials achieve a net cooling effect of 50 degrees Celsius in air, comparable to much more expensive conventionally manufactured materials.

Wide Range of Potential Applications

Thermoelectric coolers could be used in electronic devices, wearables, and medical applications such as burn treatment or muscle strain therapy. Additionally, the developed ink formulation can be applied to other materials to create high-temperature thermoelectric generators capable of producing electrical voltage from temperature differences.

This development by the ISTA team represents a significant advancement in cooling technology. 3D printing enables more cost-effective, efficient, and sustainable production of thermoelectric materials, opening new perspectives for various applications across different industries.

How do you think these 3D-printed thermoelectric materials could impact our daily lives, and what other applications can you envision for this technology? Share your ideas!

Based on content from www.sciencedaily.com and own research.